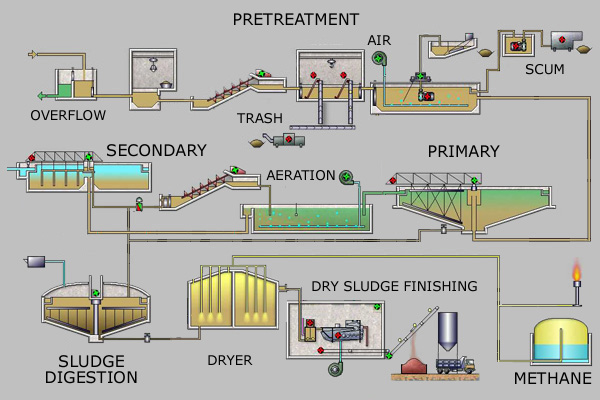

Sewage treatment & sludge disposal in WWTP plant

Sewage treatment is the process of removing contaminants from municipal wastewater, containing mainly household sewage plus some industrial wastewater. Physical, chemical, and biological processes are used to remove contaminants and produce treated wastewater that is safe enough for release into the environment. A by-product of sewage treatment is a semi-solid waste or slurry, called sewage sludge. The sludge has to undergo further treatment before being suitable for disposal or application to land.

Sewage treatment may also be referred to as wastewater treatment. However, the latter is a broader term, which can also refer to industrial wastewater. For most cities, the sewer system will also carry a proportion of industrial effluent to the sewage treatment plant, which has usually received pre-treatment at the factories themselves to reduce the pollutant load. If the sewer system is a combined sewer then it will also carry urban runoff to the sewage treatment plant. Sewage water can travel towards treatment plants via piping and in a flow aided by gravity and pumps. The first part of filtration of sewage typically includes a bar screen to filter solids and large objects which are then collected in dumpsters and disposed of in landfills. Fat and grease is also removed before the primary treatment of sewage. The sludge accumulated in a wastewater treatment process must be treated and disposed of in a safe and effective manner. The purpose of digestion is to reduce the amount of organic matter and the number of disease-causing microorganisms present in the solids. The most common treatment options include anaerobic digestion, aerobic digestion, and composting. Incineration is also used, albeit to a much lesser degree.

Sludge treatment depends on the amount of solids generated and other site-specific conditions. Composting is most often applied to small-scale plants with aerobic digestion for mid-sized operations, and anaerobic digestion for the larger-scale operations.

The sludge is sometimes passed through a so-called pre-thickener, which de-waters the sludge. Types of pre-thickeners include centrifugal sludge thickener, Screw press sludge dewatering/thickeners and belt filter presses. Dewatered sludge may be incinerated or transported offsite for disposal in a landfill or use as an agricultural soil amendment.