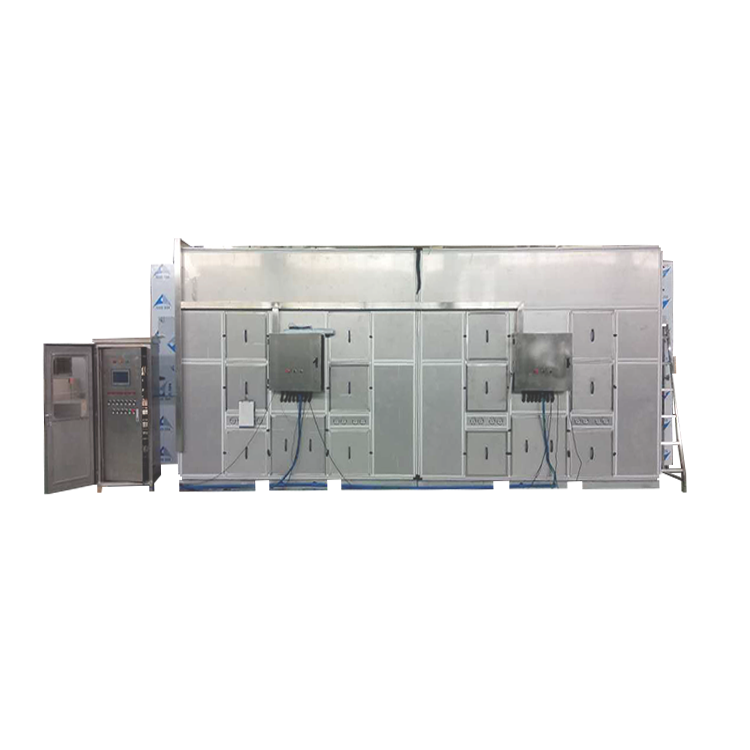

How is Low temperature sludge dryer system

Specialized in manufacturing Low temperature sludge dryer, thermal sludge dryer, Screw press sludge dewatering, Nano bubble generator, Polymer dosing preparation, offer wastewater treatment solution for our customers with best service.

Low temperature sludge dryer solution can reduce sludge moisture from 83% to 30%-10% as per specific requirement, with volume reduction by 67%, weight reduction by 80% and sterilization rate by 90%. It’s energy-efficient and eco-friendly, and has been extensively applied in municipal sludge and industrial sludge (e.g printing & dyeing, chemical, pharmacy, paper making, plating, leather). Moreover, the dried sludge meets the disposal requirement of reduction, disinfection, stabilization and re-utilization.

In front of the tremendous volumes of sludge-generated daily by the wastewater treatment plants, and the lack of sludge evacuation routes, the requirement for further sludge volume reduction after mechanical dewatering systems (centrifuges, belt filter presses, chamber filter presses, screw presses….) becomes a necessary step for sludge volume reduction.

Dryness of dried sludge: 80 to 90%

Very low temperature technology: 40°C-60°C

No smells

No contaminated air

Very high quality of condensate

Allowing heat recovery, possibility to use recycled energy

The technology of drying by low temperature costs approximately 50 to 70% less than the traditional thermic system of drying. The sludge dryers are more compact, they are more powerful in a minimum of space. One economic line of dryers with standard drying capacity of evaporation being able to go from 2.5 to 1500 kgs per hour which can be easily integrable with an installation of existing plate filter press with less costs of handling. This system respects the structure of sludge and offers an optimal efficiency in case of biological process.