Screw press VS Belt press VS Centrifuges

Resource recovery is the talk of the wastewater industry, but maybe your facility is not so progressive just yet. While drawing energy from sludge or recycling it into fertilizer may be the wave of the future, what about the simpler goal of improving on good old-fashioned dewatering?

In actuality, dewatering has come quite a long way. Considerable innovation has been applied to what has long been a high-cost operation — the process of drying and hauling sludge — even if the technologies sound familiar (e.g., screw press, belt filter press, centrifuge). Additionally, research has been conducted to identify the critical factors that affect dewatering performance, allowing for process improvements irrespective of the dewatering technology applied. Manufacturers have leveraged the same research to offer equipment that dries sludge more thoroughly and efficiently, but there is no ‘one size fits all’ technology for end users; rather, it becomes a choice based upon waste stream, size of facility, budget, staff, and other factors.

To help guide decision-making, CH2M’s global technology leader and senior principal technologist, David Oerke, PE, presented an overview of technology options and best practices for sludge management at the 2016 Water Environment Federation Technical Exhibition and Conference (WEFTEC). Key takeaways from the presentation are summarized below.

Different Sludges, Different Results

Sludge will dewater more or less effectively based on its characteristics, so an understanding of your sludge can produce better drying results and smarter procurement decisions. For example, Oerke notes that waste activated sludge (WAS) is difficult to dewater because much of the water gets attached to bacterial cells or taken up chemically in the cell structures. On the other hand, well-digested primary sludge is relatively easy to dewater.

When it comes to mechanical dewatering, higher concentrations of solids in the feed sludge yield increased amounts of cake solids, Oerke explains, since sludge that concentrates well in clarifiers or thickeners will concentrate similarly well in dewatering equipment.

3 Steps To Improved Dewatering

Although a ‘best technology’ for a given sludge-type can only be made with a side-by-side comparison under the same conditions, Oerke provided three tips to improve any dewatering operation.

1. Reduce volatile solids through better digestion.

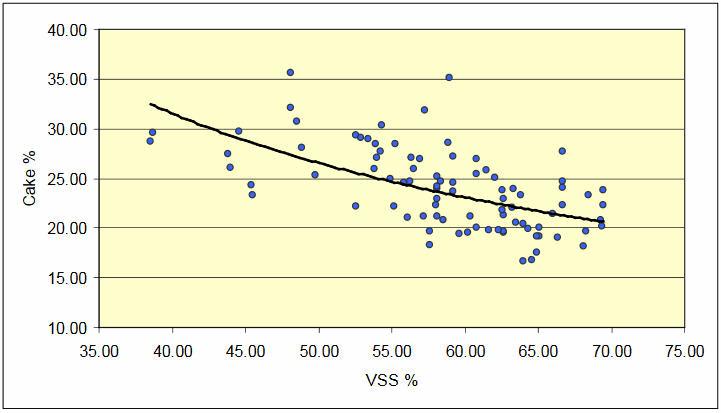

Oerke advises: “It has been shown at WWTPs [wastewater treatment plants] that a longer detention time in the digestion process and therefore a lower volatile solids percentage in the dewatered feed solids results in a greater dewatered cake solids concentration.” The graph below shows the correlation (VSS = volatile suspended solids).

Source: USEPA Process Design Manual for Sludge Treatment and Disposal, Office R&D, Cincinnati, Contract No. 625 (79-011), 1979)

2. Increase feed solids to the dewatering unit.

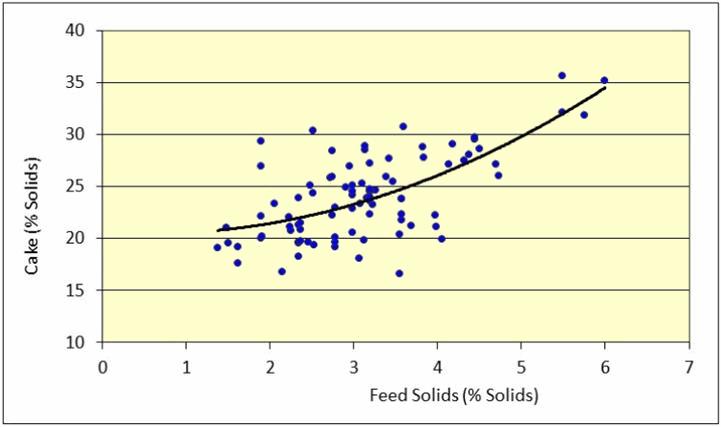

Thicker feed solids concentration generally results in drier dewatered cake concentration, as shown in the following graph.

Source: USEPA Process Design Manual for Sludge Treatment and Disposal, Office R&D, Cincinnati, Contract No. 625 (79-011), 1979)

3. Orège™

Oerke and CH2M have lined up behind Orège, a “pretreatment process [that] can increase the belt filter press dewatered cake solids concentration from aerobically and anaerobically digested biosolids by 3 to 5 percent. It has also been shown to significantly lower polymer consumption and results in an extremely clear filtrate.”

Notable for its small footprint (6 x 4 ft), Orège applies compressed air to digested biosolids to break up colloids and release trapped water. CH2M utilized the technology in providing a biosolids solution for a WWTP in Lehigh, PA — a full-scale pilot test which increased cake solids by 3 to 4 percent, reduced polymer use by 30 to 40 percent, and increased the facility’s belt filter press throughput by 50 percent.

Technology Comparison: Pros And Cons

While the tips above can be employed universally, there are distinct differences in dewatering technologies that should be considered alongside site-specific details such as available space, capital costs, and O&M. Oerke noted:

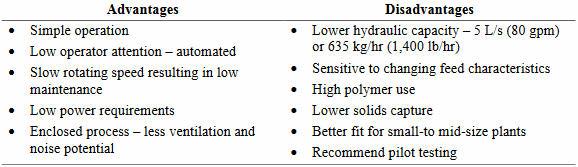

A screw press requires little operator attention and low maintenance, but consumes considerable floor space due to small hydraulic load capacity and hence a need, quite often, for multiple units — each requiring 17 feet of auger removal length. They are also less proven (i.e., less common), so pilot testing is recommended.

Table 1. Advantages and Disadvantages of Screw Presses

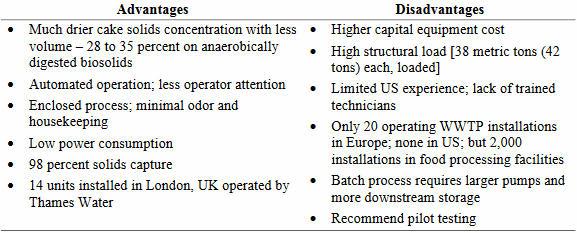

Hydraulic piston presses are also considered less proven for municipal wastewater, at least in the U.S., but have been used quite extensively for food processing (2,000 installations) and at 20 WWTPs in Europe. In those scenarios they have performed exceedingly well with regard to solids concentration and power and polymer requirements, but they also come with higher capital costs than the other options named here.

Table 2. Advantages and Disadvantages of Hydraulic Piston Presses

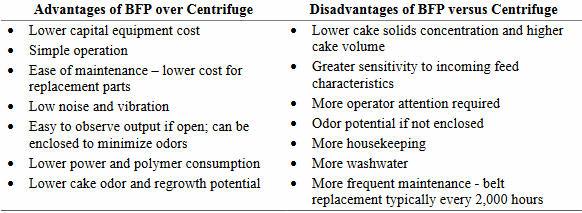

Belt filter presses and centrifuges are very common to the U.S. municipal wastewater market, thus Oerke presented their advantages and disadvantages in relation to each other. In summary, a belt filter press(BFP) is a low-cost, low-energy, low-polymer solution that is simple to operate, yet requires more operator attention and typically produces lower cake solids than a centrifuge.

Table 3. Comparison Between Belt Filter Press and Centrifuge

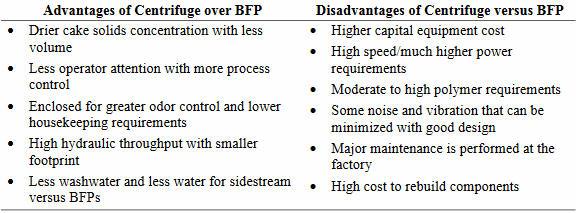

By comparison, a centrifuge produces a drier cake and has a higher throughput capacity in a smaller footprint, but also has higher capital costs, power costs, and maintenance costs.

Table 4. Comparison Between Centrifuge and Belt Filter Press

*Tables 1-4 courtesy of David Oerke/Water Environment Federation, “What Are The Best And Most Sustainable Dewatering Processes” (2016)

Armed with this information to choose the right dewatering solution and prep the sludge for optimal performance, WWTPs can greatly reduce the ballooning expense of biosolids management and disposal, while also becoming more sustainable. Now that’s progress, by anyone’s definition.