Product Name: Screw Press Sludge Dewatering ST132

Screw Press Sludge Dewatering

Sludge thickening

Sludge Dehydrator

Multi-disk sludge dewatering

Product description: Screw Press Sludge Dewatering ST132

Product details

Screw Press Sludge Dewatering ST132

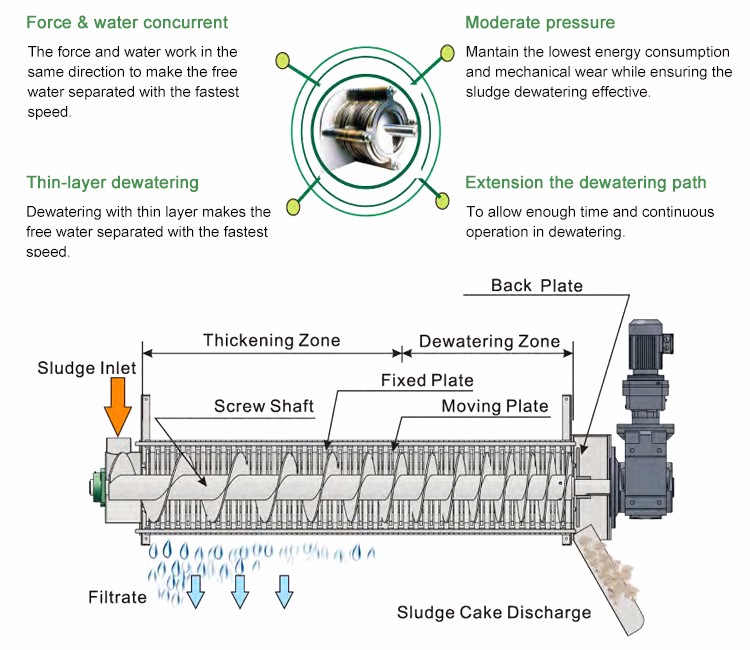

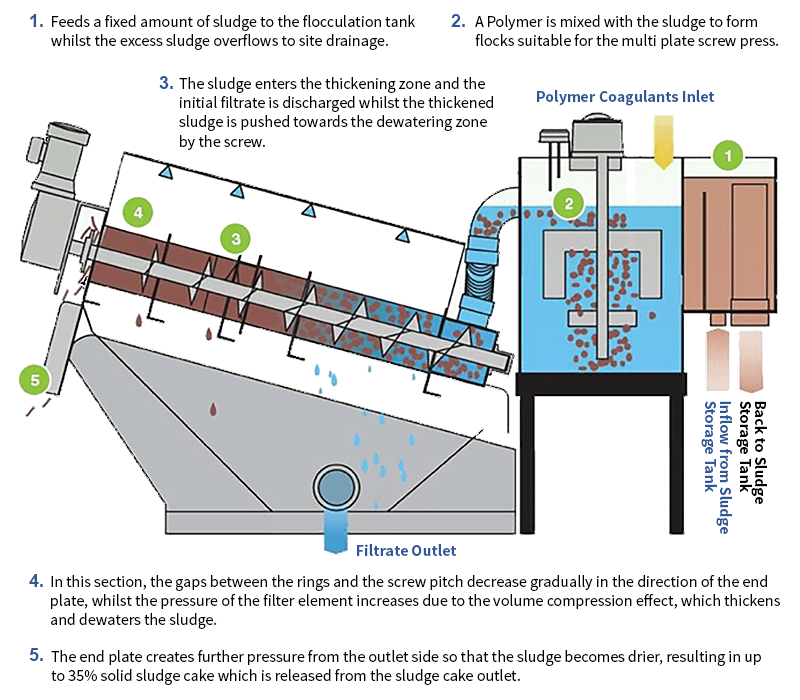

Screw press sludge dewatering/ thickening/ thickener also called Multi-Disc Screw Press , it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. Minimized waste water and saving the cost of transport.

Screw press using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge.

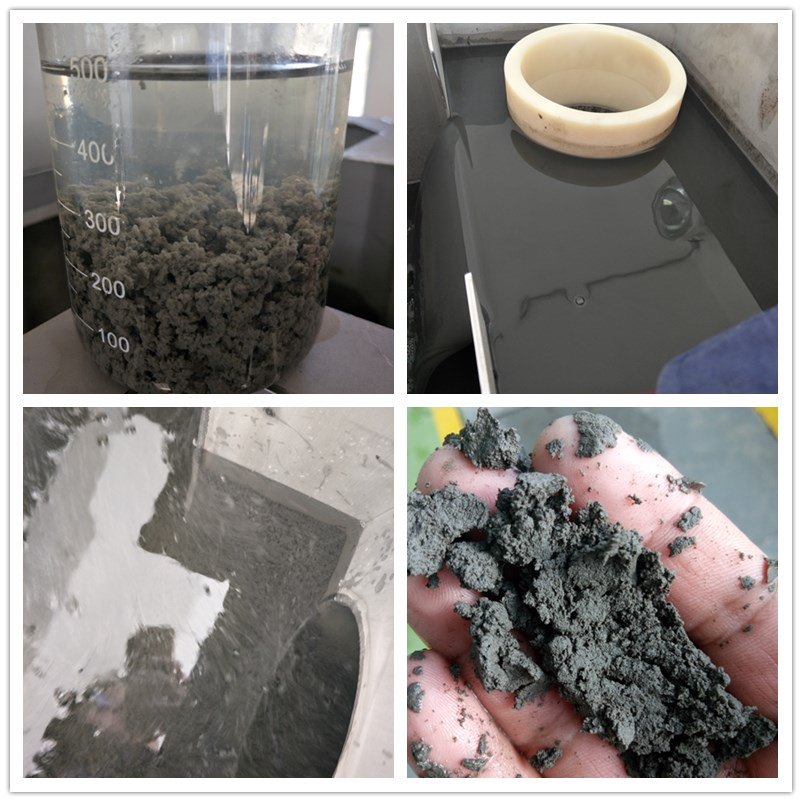

Sludge Dewatering Press is a high performance sludge dewatering system. It utilizes a central screw auger and a slowly oscillating multi-disk filter to gradually increase pressure on flocculated sludge to produce an exceptionally dry sludge cake. With electrical, water and polymer usage, and high capture rates the system is very cost effective.

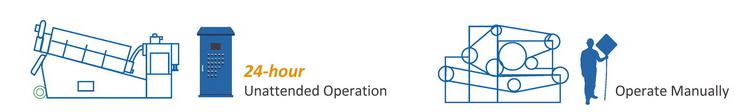

Sludge Dewatering Press can be provided with all equipment required for dewatering included and factory mounted, piped and wired on a single stainless steel skid. This equipment includes the sludge pump, wash water pump, polymer dosing system and control panel. The system features fully automated one pushbutton startup and shutdown. Once started up the system can run unattended and can be set to shutdown automatically with no operator intervention.

Sludge Dewatering Press is constructed entirely of stainless steel 304/316.

Features:

• Enclosed to minimize odors and noise (lower than 65Db)

• Very low wash water usage(1/8 compared with belt press)

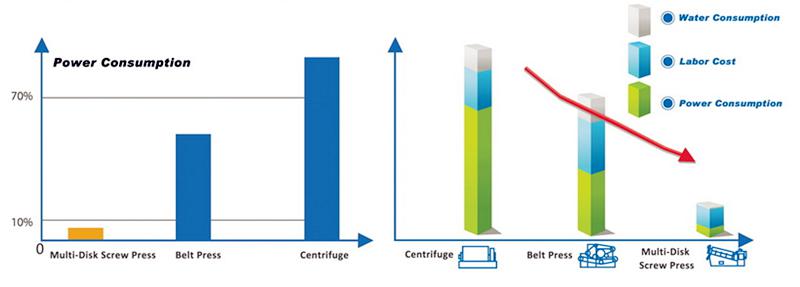

• Very low power consumption(1/20 compared with centrifuge)

• High cake solids

• Minimal operator requirement

• Easy to operate and maintain

• Auto start-up, run and shutdown

• Touch screen operation optional

• Sludge Flow and Cake Monitoring System

Advantage:

Widely application

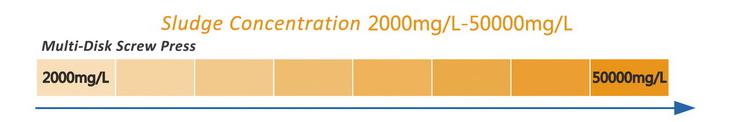

Exclusive pre-concentration design , applicable sludge concentration of 2000mg/L~50000mg/L Due to innovation of the structure design .Highly suitable to various high and low concentration sludge most especially the oily ones.

Widely application range including municipal sewage ,food wastewater,slaughter house ,printing and dyeing, oil chemical industry, paper making ,leather ,pharmacy and other different kinds of sludge dewatering.

Clogging free

Due to the moving of the fixed rings and moving rings self -cleaning .The ubiquitous clogging is avoided .Handing oily sludge without trouble while separating the water from the sludge easily . Above all , no need large quantiry of flushing water and no odor ,no secondary pollution during the sludge dewatering process .

Operation Cost saving

Screw Press relles on the inner pressure of the filter chamber and the rotating speed is as slow as 2~4rpm. The average unit power consumption is only 0.1~0.01kwh/kg-DS(1/8 of Belt Filter Press and 1/20 of Centrifuge) . Greatly reduce the running cost of wastewater treatment system

Automatic Operation

High efficient for oily sludge

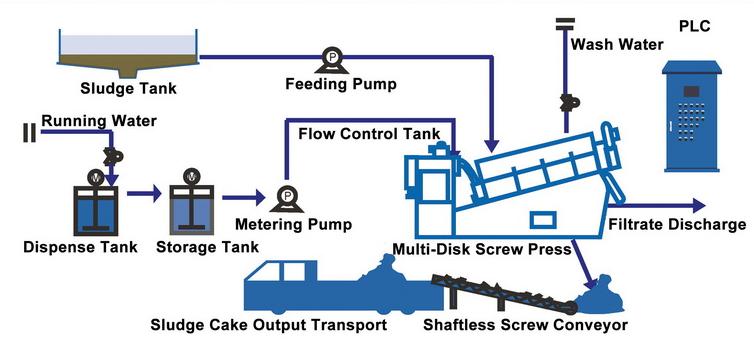

Flow Chart:

Projects:

Chemical Project

Dairy Wastewater Project

Chemical Project:

Specification:

| Model | DS Capacity | Sludge Treating Capacity | Screw specification | Mud cake outlet to ground Distance(mm) | Dimension(mm) | Net Weight | Operation Weight | ||||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | Length(L) | Width(W) | Height(H) | ||||||

| ST101 | 3~5kg/h | ~0.5m3/h | ~0.25m3/h | ~0.2m3/h | ~0.15m3/h | ~0.14m3/h | φ100×1 | 215 | 1850 | 740 | 1040 | 220kg | 315kg |

| ST131 | 6~12kg/h | ~1m3/h | ~0.5m3/h | ~0.4m3/h | ~0.3m3/h | ~0.28m3/h | φ130×1 | 250 | 2000 | 785 | 1040 | 250kg | 395kg |

| ST201 | 9~20kg/h | ~1.5m3/h | ~0.75m3/h | ~0.6m3/h | ~0.5m3/h | ~0.4m3/h | φ200×1 | 350 | 2510 | 900 | 1300 | 420kg | 540kg |

| ST202 | 18~40kg/h | ~3m3/h | ~1.5m3/h | ~1.2m3/h | ~1.0m3/h | ~0.8m3/h | φ200×2 | 350 | 2560 | 1050 | 1300 | 550kg | 660kg |

| ST301 | 30~60kg/h | ~5m3/h | ~2.5m3/h | ~2m3/h | ~1.5m3/h | ~1.4m3/h | φ300×1 | 530 | 3330 | 1005 | 1760 | 900kg | 1300kg |

| ST302 | 60~120kg/h | ~10m3/h | ~5m3/h | ~4m3/h | ~3m3/h | ~2.8m3/h | φ300×2 | 530 | 3530 | 1290 | 1760 | 1350kg | 2000kg |

| ST303 | 90~180kg/h | ~15m3/h | ~7.5m3/h | ~6m3/h | ~4.5m3/h | ~4.2m3/h | φ300×3 | 530 | 3680 | 1620 | 1760 | 1900kg | 2700kg |

| ST304 | 120~240kg/h | ~20m3/h | ~10m3/h | ~8m3/h | ~6m3/h | ~5.6m3/h | φ300×4 | 530 | 3830 | 2010 | 1760 | 2500kg | 3600kg |

| ST351 | 65~100kg/h | ~10m3/h | ~5m3/h | ~4m3/h | ~3m3/h | ~2.4m3/h | φ350×1 | 570 | 4005 | 1100 | 2130 | 1100kg | 2000kg |

| ST352 | 130~200kg/h | ~20m3/h | ~10m3/h | ~8m3/h | ~6m3/h | ~4.8m3/h | φ350×2 | 570 | 4390 | 1650 | 2130 | 2100kg | 3250kg |

| ST353 | 195~300kg/h | ~30m3/h | ~15m3/h | ~12m3/h | ~9m3/h | ~7.2m3/h | φ350×3 | 570 | 4520 | 1980 | 2130 | 3100kg | 4600kg |

| ST354 | 260~400kg/h | ~40m3/h | ~20m3/h | ~16m3/h | ~12m3/h | ~9.6m3/h | φ350×4 | 570 | 4750 | 2715 | 2130 | 4100kg | 5700kg |

| ST401 | 95~160kg/h | ~13m3/h | ~6.5m3/h | ~5m3/h | ~4m3/h | ~3.2m3/h | φ400×1 | 660 | 4680 | 1110 | 2100 | 2200kg | 4200kg |

| ST402 | 190~320kg/h | ~25m3/h |

Related Products | ||||||||||